Revolutionizing the Additive Manufacturing Industry with AlSi10Mg Powder

The additive manufacturing industry is constantly evolving, with new technologies and materials pushing the boundaries of what is possible. One material that has been making waves in the industry is AlSi10Mg powder.

The Advantages of AlSi10Mg Powder

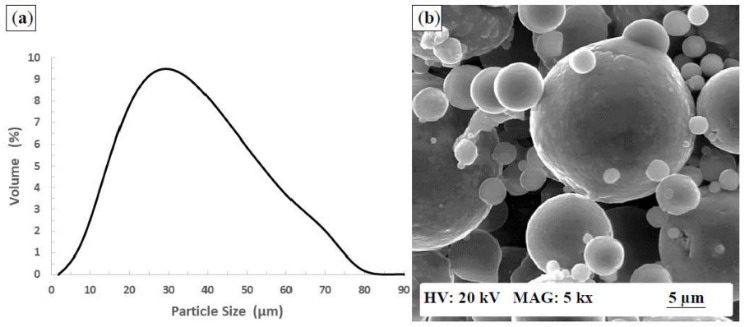

AlSi10Mg powder is a high-performance aluminum silicon magnesium alloy that is specifically designed for use in additive manufacturing processes such as selective laser melting (SLM) and direct metal laser sintering (DMLS). This material offers a range of advantages that make it ideal for a wide variety of applications.

One of the key advantages of AlSi10Mg powder is its excellent mechanical properties, including high strength and stiffness. This makes it suitable for use in demanding applications where strength and durability are essential. In addition, this material has good thermal conductivity, which can help to improve the performance of components that require efficient heat dissipation.

Applications of AlSi10Mg Powder

AlSi10Mg powder is being used in a wide range of industries, including aerospace, automotive, and medical. In the aerospace industry, this material is being used to manufacture lightweight yet strong components for aircraft and spacecraft. In the automotive industry, AlSi10Mg powder is being used to produce parts that are both lightweight and durable, helping to improve fuel efficiency and performance.

In the medical industry, AlSi10Mg powder is being used to create custom implants and prosthetics that are tailored to the specific needs of individual patients. This material offers biocompatibility and corrosion resistance, making it ideal for use in medical applications where long-term performance is essential.

Read more about AlSi10Mg Powder Price here.

Overall, AlSi10Mg powder is revolutionizing the additive manufacturing industry with its unique combination of mechanical properties and versatility. As technology continues to advance, this material is likely to play an even greater role in the development of new and innovative products across a wide range of industries.