Metal Powders for 3D Printing and Additive Manufacturing: Revolutionizing Industrial Production

The advent of 3D printing and additive manufacturing has marked a revolutionary leap in how industries conceptualize, prototype, and manufacture products. At the heart of this transformative technology lie Metal Powders for 3D Printing and Additive Manufacturing, materials that have become indispensable for creating complex, high-strength, and lightweight components across various sectors. Among these, Ti6Al4V powder, AlSi10Mg powder, and other specialized Additive Manufacturing Metal Powders stand out for their unique properties and applications.

Understanding Ti6Al4V Powder in Additive Manufacturing

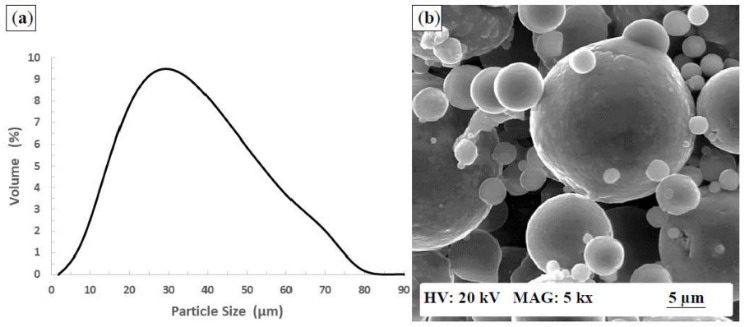

Ti6Al4V powder, also known as Grade 5 Titanium, is renowned for its exceptional strength, lightness, and corrosion resistance. This alloy—a combination of titanium, aluminum, and vanadium—is predominantly used in aerospace, medical, and automotive industries. Its compatibility with the human body makes it an excellent choice for medical implants, while its strength-to-weight ratio is ideal for aerospace components. The ability to produce complex shapes with minimal waste makes Ti6Al4V powder a preferred material in additive manufacturing.

Read more about ti6al4v powder price here.

Exploring AlSi10Mg Powder’s Role

AlSi10Mg powder is another key player in the additive manufacturing arena. This aluminum alloy powder is favored for its good thermal properties, high electrical conductivity, and excellent casting ability. Its versatility makes it suitable for automotive parts, consumer goods, and intricate architectural pieces. With AlSi10Mg powder, manufacturers can achieve detailed geometries that are otherwise challenging to produce, making it an invaluable asset in 3D printing applications.

The Advantages of Additive Manufacturing Metal Powder

The broad spectrum of Additive Manufacturing Metal Powder extends beyond Ti6Al4V and AlSi10Mg powders. These materials offer numerous advantages, including the capacity to fabricate complex and bespoke designs, reduce material waste, shorten production cycles, and decrease overall manufacturing costs. Furthermore, the use of metal powders in additive manufacturing facilitates the creation of components with superior mechanical and thermal properties than those produced through conventional methods, thereby enhancing product performance and longevity.

Fueling Innovation Across Industries

The strategic integration of Metal Powders for 3D Printing and Additive Manufacturing is fueling innovation and efficiency across an array of industries. From aerospace and automotive to healthcare and consumer goods, these advanced materials are enabling companies to push the boundaries of what’s possible, offering unprecedented design freedom, customization capabilities, and environmental benefits. As technology continues to evolve, the demand for specialized metal powders like Ti6Al4V and AlSi10Mg is set to rise, heralding a new era of industrial manufacturing that is smarter, faster, and more sustainable.

Read more about Additive Manufacturing Metal Powder here.

In conclusion, the role of Metal Powders for 3D Printing and Additive Manufacturing cannot be overstated. They are not just transforming manufacturing processes but are also paving the way for innovations that were once deemed alsi10mg powder price impossible. As the industry evolves, the exploration and adoption of new and specialized metal powders will undoubtedly continue, further expanding the horizons of additive manufacturing and its potential to reshape the world.