Innovative Techniques in LSR Injection Molding: A Breakthrough for Modern Manufacturing

As industries push the boundaries of technology, LSR injection molding has emerged as a frontrunner in material innovation. This technique, celebrated for its precision and efficiency, is becoming increasingly essential in sectors ranging from automotive to healthcare. By utilizing Liquid Silicone Rubber (LSR), manufacturers can achieve superior flexibility, heat resistance, and durability.

What is LSR Injection Molding?

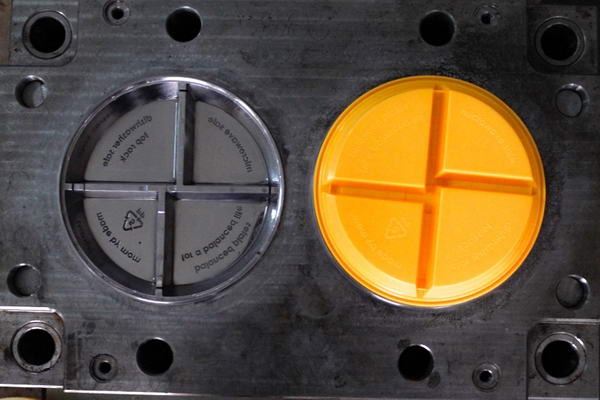

At its core, LSR injection molding is a process used to produce flexible, durable parts. The method involves injecting liquid silicone into a mold to create components that are intricate in design yet robust in performance. Here are some of the primary advantages:

- Precision: LSR injection molding allows for the creation of complex geometries.

- Cost-efficiency: The process minimizes waste and reduces production time.

- Versatility: It’s applicable across various industries due to its adaptable properties.

The Benefits of LSR in Various Industries

Each industry has unique needs, and LSR injection molding meets these demands with unmatched adaptability.

- Medical Devices: LSR is biocompatible and resistant to sterilization processes, making it ideal for medical implants and devices.

- Automotive: The material’s heat resistance and flexibility ensure longevity and performance in vehicle components such as seals and gaskets.

- Consumer Goods: From kitchenware to electronics, LSR offers a non-toxic, safe solution for household items.

Choosing the Right LSR Solution

For businesses looking to implement LSR injection molding, selecting the right partner is critical. Quality manufacturers offer customizable solutions, ensuring that each component meets stringent standards without compromising on quality or innovation.

FAQs About LSR Injection Molding

Q: Is LSR injection molding eco-friendly?

A: Yes, it is. The process significantly reduces material waste, and the end products are often recyclable.

Q: What is the turnaround time for LSR injection molded products?

A: Turnaround can vary, but due to the efficiency of the process, it often allows for faster production cycles than traditional methods.

The use of LSR injection molding is transforming how industries function, offering possibilities that were once thought impossible. By embracing these techniques, manufacturers can not only improve product quality but also foster sustainable and innovative practices in various sectors.