Fundamentals of Electric Motors and Electric Drives

The rotational pace of an asynchronous motor provided trough an AC chopper could be changed in a really restricted extent. With our experience and expertise, we are in a position to react shortly and flexibly and offer DKC02.3-040-7-FW the most environment friendly solution for all customer necessities. The vehicle control unit as central E/E structure part for all powertrain varieties.

The inverter achieves the next efficiency by way of silicon carbide semiconductor expertise for a fair higher DKC06.3-040-7-FW vary of electrical autos. Electromagnetic motors derive torque from the vector product of the interacting fields.

Hydraulic adjustable speed drives

The power controlling of the motor could be accomplished in such a method that the electrical motor sends out the speed-torque characteristic which is critical with the load. During the temporary operations, the extreme present might be drawn from the ability supply. Unlike the rotor velocity outcomes, estimated rotor flux isn’t precisely approaching the reference (see Figure 7), which is nonetheless near actual results. The “actual value” proven in Figure 7 for comparison is obtained from regular flux calculation technique via measured voltages and currents and might be thought-about as precise flux as a end result of proof of incomputable applications. It is obvious that the estimated flux with +200% resistance, 50% load torque, or +200% stator leakage inductance isn’t influenced by these disturbances dramatically. In a series HEV (SHEV), the internal combustion engine (ICE) is the main energy source that converts the original vitality in gasoline to mechanical power.

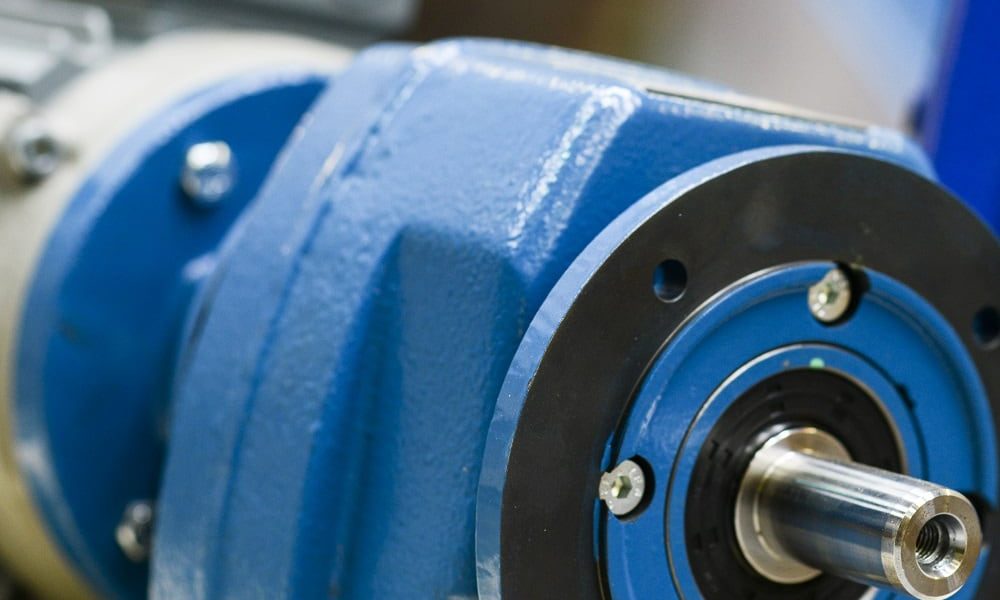

Crossing the gaps additionally generates electrical noise; sparking generates RFI. Brushes finally wear out and require alternative, and the commutator itself is topic to put on and maintenance or alternative. The commutator assembly on a big motor is a expensive factor, requiring precision assembly of many parts. On small motors, the commutator is often completely DKC03.3-040-7-FW integrated into the rotor, so replacing it normally requires changing the rotor. A commonplace drive system incorporates a quantity of electrical motors, coupled with a management system that regulates the motor shaft’s rotation. The key constituents of electric drives comprise the electric motor, the energy-transmitting system, and the working (or driven) machine.

Electric Motors and Drives

Cabling will be required for energy and control signals to the motor, along with suitable provide for operation of the drive itself. Totally enclosed motors do not have any air openings; subsequently, there is not any free exchange of air between the inside and outdoors of the motor body. Normally, the rotor has air circulating fins at every end to circulate the trapped inside air and improve convection cooling to the body. Power scores of these motors have been restricted since they can overheat.

What is an Electric Drive?

Connections are made to the slip rings through brushes and in turn to an exterior resistor, which may be adjusted to alter the motor speed-torque characteristics. For a wound-rotor induction, increasing the external resistance of the management will cause the peak torque of the motor to be reached at decrease speeds until the height torque happens at around zero pace.

Slip ring induction motor has high beginning torque and huge overload capability. Also, the speed of a slip ring induction motor can be changed up to 50% of its normal pace. In this region, the power and torque are each DKC01.3-040-7-FW positive, so the ability developed is constructive and the machine works as a motor supplying mechanical vitality. The robust constructions and low cost of the AC motor make it very fascinating for a variety of makes use of.

For the longer term, power switching gadgets, very low on-resistance, and high-temperature operation are anticipated to simplify the cooling system of the converter. Silicon Carbide (SiC) or Gallium Nitride (GaN) gadgets are attainable candidates. For the middle- and low-power modules, lower breakdown voltage is required.