Carbon Fiber vs Carbon Fiber Fiberglass vs Fiberglass

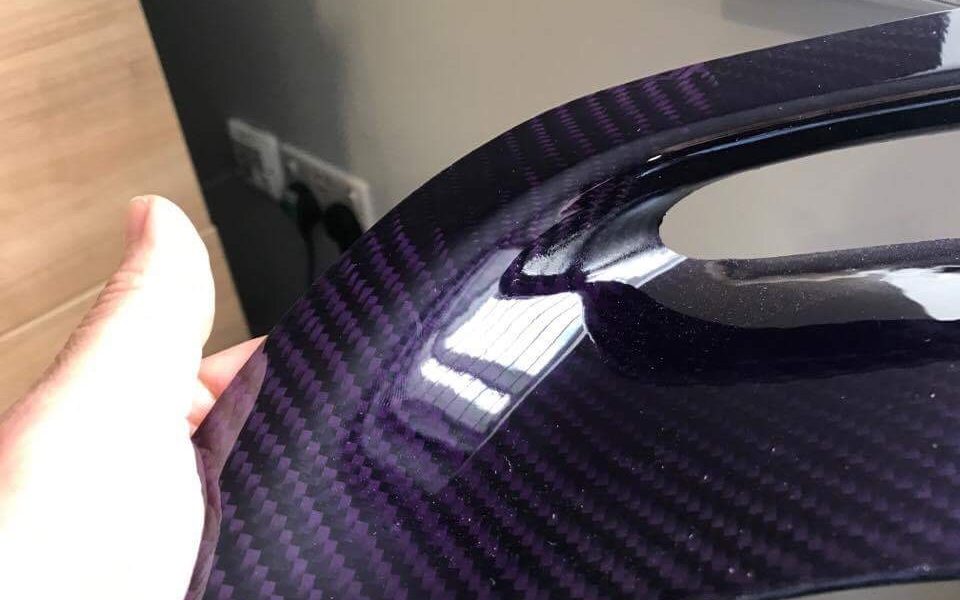

Another feature of carbon fibre is that it has a distinctive, unique appearance. You can tell at first glance that a part is made of this specific material. Both the bodywork and interior of high-end vehicles utilise CFRPs to achieve the level of details impossible with the previously used plastics and aluminium. The look is so characteristic that many manufacturers offer faux CFRP elements made of various types of less expensive plastics imitating the sleek surface of carbon fibre car parts. They also emphasized there are no “announced” large-scale carbon fiber automotive projects in today’s pipeline, projecting only a 2.4% CAGR to 2026, mainly for motorsports, customization and low-volume niche platforms.

Lightweight yet extremely strong, the material can be used to make cars that are safer and more fuel efficient. It can also lower a car’s center of gravity when applied to upper body parts, making it more agile and exciting to drive. Carbon fiber is made of thin, strong crystalline filaments of carbon that is used to strengthen material. Carbon fiber can be thinner than a strand of human hair and gets its strength when twisted together like yarn. Then it can be woven together to form cloth and if needed to take a permanent shape, carbon fiber can be laid over a mold and coated in resin or plastic. Our high-temperature carbon fiber panels are made with a specially formulated high-temperature, high-strength epoxy resin.

Thin carbon fiber sheets (up to .5mm) can be cut with scissors or a sharp razor knife. For thicker carbon fiber plates and panels, abrasive cutting wheels and Dremel tools are best.

Carbon Fiber Parts Are Durable

You can drive with confidence thanks to our premium materials and quality assurance. Our products are proudly designed & engineered in the United States of America. Check out our latest material option, offered on a select number of products. Plush Automotive Limited is a credit broker, not a lender and is authorised and regulated by the Financial Conduct Authority (FRN ). We will introduce you exclusively to Omni Capital Retail finance products provided by Omni Capital Retail finance Limited through the Deko platform. Now the two skins are bonded together, the final stage is to trim and finish off the edge of the upper skin.

Composites Materials

This is a critical step; without a good mold, it’s almost impossible to make a good carbon fiber part. Composite molds are particularly complex, so it’s important to use a team with extensive experience. CFRP consists of a matrix (typically a polymer resin) and a reinforcement (carbon fiber). Next, a breather fabric is placed over the peel ply.The EZ~Spray™ Silicone 20 vacuum bag is repositioned. Smooth-On’s EpoxAmite™ Epoxy Laminating Resin was used to make the part.

How To Fabricate Automotive Fiberglass & Carbon Fiber Parts

It’s this combination of fiber and resin that gives a composite its strength, stiffness and durability properties. In the composites industry, we usually specify the fiber used in a given composite part. So, we say “carbon fiber composite” or “glass fiber composite.” To the layperson, use of the phrase “carbon fiber” usually means carbon fiber composite — carbon fiber combined with a resin (usually epoxy).

Read more about carbon keychain here.

Manufacturers operating in the automotive & transportation industry are recovering from the losses caused due to disturbed ecosystem and reduction in sales of automotive vehicles. However, with relaxation in COVID-19 rules, manufacturers in the global automotive carbon fiber composites parts market are focusing on increasing their production capacity to gain revenue benefits.

The surging demand and acceptance of carbon composite parts for manufacturing sports cars in European countries, including Italy and France is also driving the global market. Lightweight components used in these cars increase the speed of cars and boost performance.