Exploring the Intricacies of Liquid Silicone Rubber Injection Molding

In recent years, the use of Liquid Silicone Rubber (LSR) has surged, thanks to its remarkable flexibility, durability, and overall performance in various applications. The LSR injection molding process has become a key method in numerous industries, ranging from automotive to healthcare. This article delves into the nuances, benefits, and uses of this fascinating manufacturing technique.

Understanding LSR Injection Molding

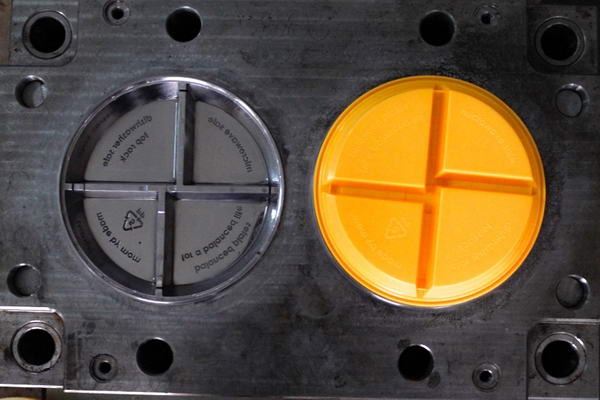

LSR injection molding is a unique process that involves injecting a two-part liquid silicone compound into a pre-formed mold. This technique allows for the creation of complex shapes and intricate details, which would be challenging to achieve through other molding processes. The primary advantages of LSR injection are:

- Precision: Capable of producing highly detailed and accurate parts.

- Efficiency: Faster cycle times compared to traditional molding techniques.

- Versatility: Suitable for a variety of applications, including medical devices and automotive components.

Benefits of LSR in Various Industries

The versatility of Liquid Silicone Rubber makes it an ideal choice across multiple sectors:

- Healthcare: Non-reactive properties make it perfect for medical devices such as catheters and seals.

- Automotive: Resilience to extreme temperatures and resistance to chemicals ensure safety and durability.

- Consumer Goods: Products like baby bottle nipples benefit from LSR’s non-toxic nature.

FAQs About LSR Injection

- What is the main difference between LSR and traditional rubber?

The key difference lies in their curing processes. LSR is a thermoset material, meaning it hardens when heated. - Can LSR withstand high temperatures?

Yes, LSR is known for its capability to endure both high and low temperatures, making it suitable for various environments. - Is LSR injection molding cost-effective?

While the initial investment might be higher, the efficiency and reduced cycle times offer long-term cost savings.

For those seeking specialized services in this field, LSR injection molding services are offered by experienced professionals who understand the intricacies of this advanced technique.

In conclusion, the advancement of LSR injection molding is set to redefine the capabilities and possibilities in product manufacturing, offering an exciting avenue for innovation and quality in various applications.